경주 오도리 부채꼴 주상절리의 독특한 용암 지형

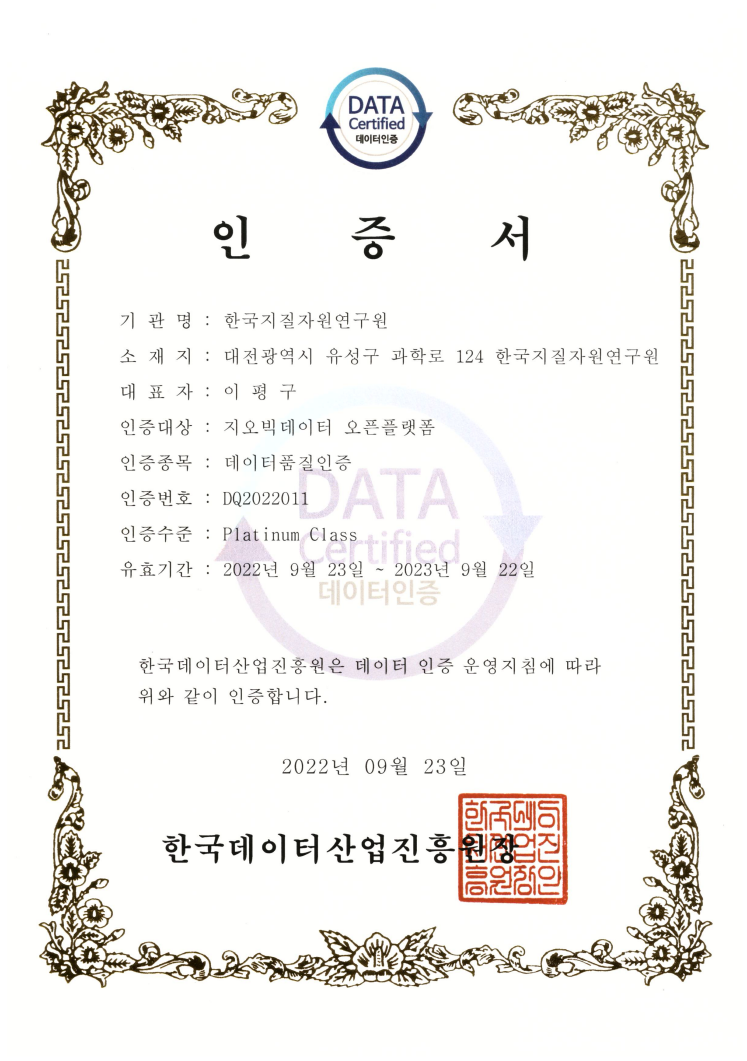

Data Quality Certification (DQC-V)

| Data type | KIGAM 보고서 |

|---|---|

| Title | 하동지역 티탄 철석의 선광 및 활용 경제성 연구 |

| Author | 양정일 |

| Language | KOR |

| Call Number | KR-98-C-32-1998-R |

| Publication Information | 韓國資源硏究所, 1998 |

| Abstract | 1) The result of chemical analysis on head ore shows that it contains 9.31% TiO₂, which is slightly high grade comparing 5.38%TiO₂ of head ore obtained in previous year.2) The result of microscopic analysis on head ore shows that gangue minerals consists of mainly anorthite, hornblend and small amount of quartz, chlorite, pyroxene. Paticularly, heavy minerals such as garnet, zircon, pyrohotite and magnetic appear in gangue mineral product obtained in the cleaning process. 3) Cobbing test of magnetic separation was carried out for the recovery of coarse magnetic product on the initial treatment process. The magnetic separation using rare earth magnetic separator was performed at conditions of 250rpm roll speed, 0 splitter position and 1,000gr./min. feed rate. The magnetic product contains 12.10%TiO₂ and is recovered with 92.47T recovery. The cobbing separation provides an effect not only to reduce 30% of feeding amount for the next grinding process but also increase the grade of ore for obtaining economical operation. 4) The result of gravity separation test using shaking table concentrator shows that ilmenite concentrate containing 41.25TiO₂ is obtained with 57.78% recovery at the initial recovery stage. 5) The ilmenite concentrate obtained by gravity separation appears insufficient grade for the use of Ti refining. So, magnetic separation method is adopted to increase the grade of the ilmenite concentrate having 41.25%TiO₂. The ilmenite concentrate obtained using cross belt magnetic separator is recovered with 91.02% recovery at magnetic intensity between 10 Ampere and 17.5 Ampere. The ilmenite concentrate obtained by magnetic separation 46.01%TiO₂. 6) The result of magnetic separation varying magnetic intensities shows that non-mag. products obtained at 30 Ampere and 20-30 Ampere, respectively contain high grade zircon and garnet. The mag. product obtained at 10 Ampere contains pyrohotite. 7) The ilmenite concentrate obtained by magnetic separation does not contain sufficient grade for use Ti refining yet. So, electrostatic separation is adopted to reject the impurity minerals induced in the ilmenite concentrate. The conditions of electrostatic separation are 22 Voltage of electric intensity, screen length at 6, feed velocity at 8 and feed rate 70gr./min.. The result of electrostatic separation test shows that the final ilmentie concentrate containing 50.27%TiO₂ is obtained with 90.01% recovery.8) Based on calculation of total recovery of the final ilmenite concentrate containing 50.27%TiO₂, it appears 44.7% recovery from head ore containing 9.31%TiO₂, when it is treated by combination process of gravity separation, magnetic separation and electrostatic separation. 9) The final ilmenite concentrate containg 50.27%TiO₂ is evaluted by Hankook Titanium Co. The result shows that the ilmenite concentrate is resonable for Ti refining, because it contains low impurities such as 0.01%CrO₃ and 0.14%V₂O5, except containing a little bit low active titanium di-oxide component. 10) Total result of separating test shows that ilmenite concentrate of 50.27%TiO₂ for use of Ti refining is obtained with 44.8% recovery and another ilmenite concentrate containing 19%TiO₂ for use of protecting erosion of iron hearth refractor is obtained 33% recovery, respectively. 11) The result of applying test on the tailing product having 3.61%TiO₂ grade and 80.9%wt. shows that it can be used as subsidiary material for cement manufacture |

| Page | 260 p. |

| Keyword | 하동, 티탄, 티탄철석, 선광, 티타늄, 시멘트, 회장석 |

| Source |

http://library.kigam.re.kr/report/1998/하동지역티탄철석의선광및활용경제성연구.pdf |

Comments