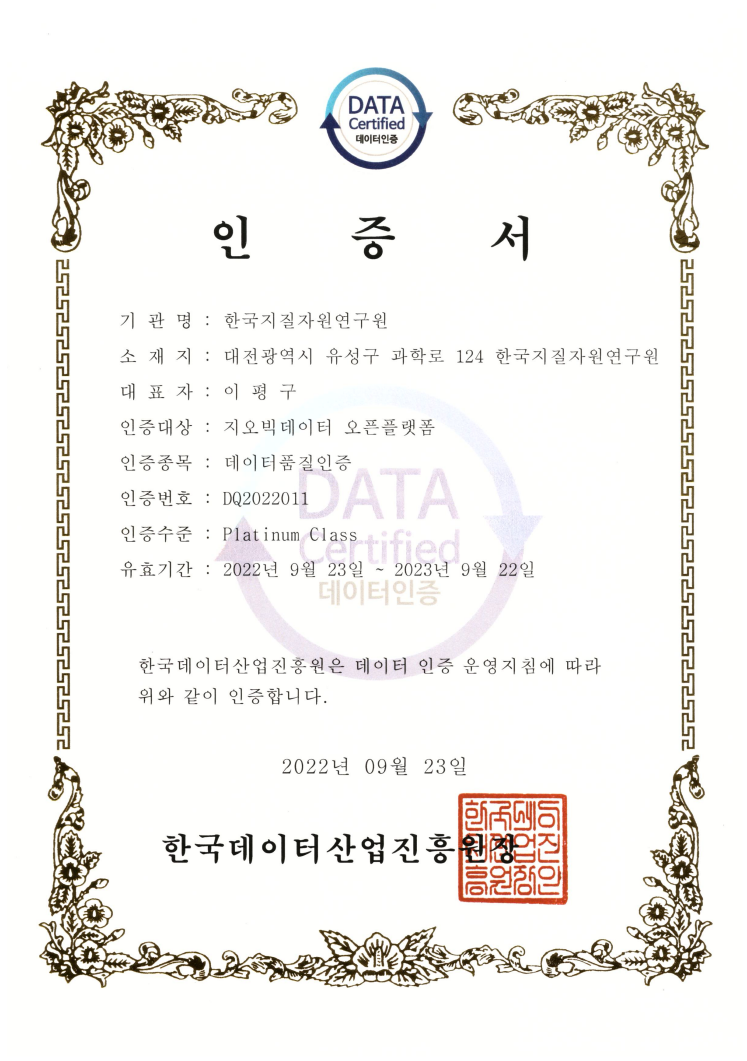

Data Quality Certification (DQC-V)

| Data type | KIGAM 보고서 |

|---|---|

| Title | 금속산화물 微粉體 제조 및 활용 연구 |

| Author | 박형규 |

| Language | KOR |

| Call Number | KR-98-C-27-1998-R |

| Publication Information | 韓國資源硏究所, 1998 |

| Abstract | Metal oxide fine powders are used as new materials in many industrial fields. It is necessary to develope the technology for manufacturing such powders to improve the domestic industry. The purpose of present research is to develop technologies for the preparation and utilization of metal oxide fine powders. This research project is consisted of two main subjects. One is to develope processing technology on ultrafine silica powder of less than 100 nanometer in particle size, the other is on antimony trioxide powder which is used as flame retardant in plastic rubber, and textile industries. The summary of each subject is as follows ; Subject I. Preparation of Ultrafine Silica Powder; Ultrafine silica (SiO₂) powder was synthesized by the gas-phase thermal oxidation of tetraethoxysilane (TEOS) in a laminar diffusion flame reactor. A diffusion flame burner composed of five concentric stainless tubes was used as a semi-bench scale aerosol generator. The maximum temperature in the stabel diffusion flame was about 1600℃ at the radial distance of 4mm from the center of the burner and at the height of 1 cm from the burner surface. For the preparation of silica particles, initial concentration of TEOS and gas composition of the flame were chosen as experimental variables. Ultrfine silica powder less than 50nm in average particle diameter were synthesized. As the initial TEOS concentration increased, average particle diameter of silica also increased. Larger particles were produced with the injection of air instead of Ar through the 2nd tube at the same total gas flow rate in the flame. Ultrafine silica particles obtained from the present study were tested as an additive for the production of Epoxy Molding Compound (EMC). Important physical properties of EMC such as spiral flow, and bleed and flash were measured. The results showed that silica particles from the present study were very compatible with the commercial product of silica particless for the preparation of the EMC. For the application of ultrafine silica powders, coal ash produced as domestic wastes was mixed with ultrafine silica particles, and the mixture was treated the surface characteristics using polydimethylsiloxane and isopropyl alcohol to obtain the high of hydrophobicity of the powders. The powders having a hydrophobicity were tested to remove a few king of oils on the surface of aqueous solution. Subject II. Preparation of Antimony Trioxide Powder ; Antimony trioxide is used as flame retardant material in plastic, rubber, and textile industries. It was carried out to establish porcessing technology of antimony trioxide, and provide for smelting of metallic antimony by domestic industries. Also, domestic market of antimony trioxide was surveyed. Commercial antimony trioxide has been manufactured through two steps: the first is to extract antimony metal from Stibnite ore, and the second is to evaporize and oxidize metallic antimony. In this study, it was focused on the second step because primary antimony has not been produced domestically. An equipment for melting and vaporizing of metallic antimony was experimentally prepared. Antimony metal was melted in magnesia cricible, and reacted with air to oxidize into antimony trioxide powder in the equipment by use of suction blower. The powder was collected through bag filter. The crystal form of the antimony trioxide sample was senarmontite. The shape of the powder was widely spherical. It is considered that antimony trioxide could be prepared effectively through the experiment |

| Page | 106 p. |

| Keyword | 금속산화물, 미분체, 제조, 활용, 초미립, 안티모니, 실리카 |

| Source |

Comments