경주 오도리 부채꼴 주상절리의 독특한 용암 지형

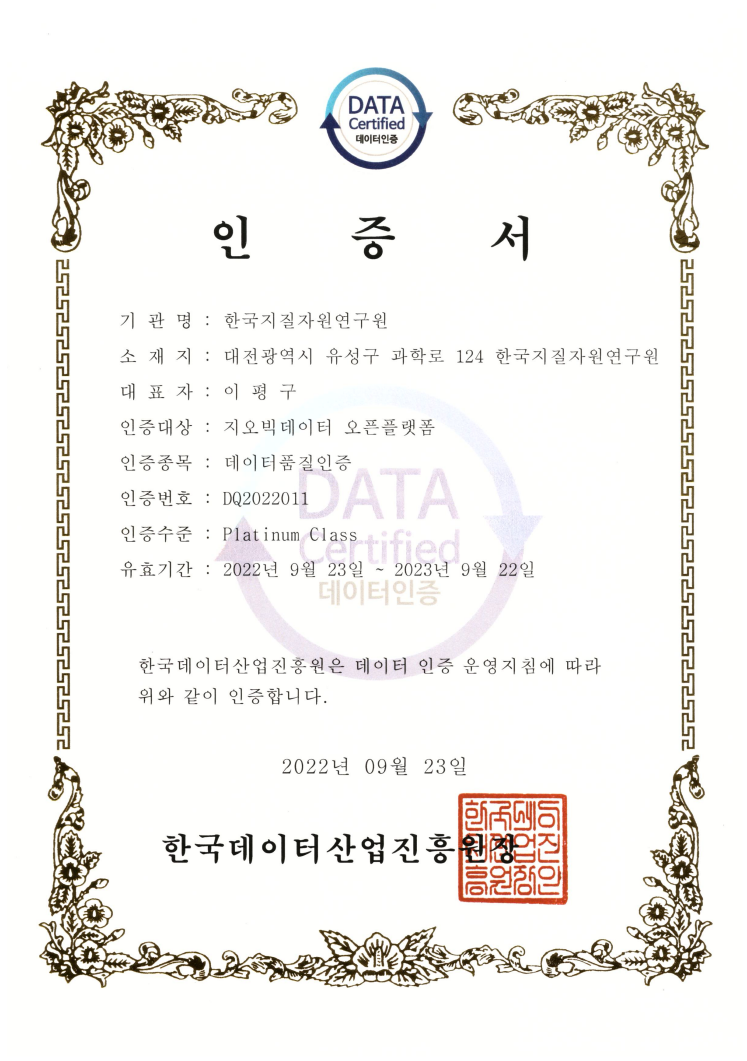

데이터 품질 인증서

| 자료유형 | KIGAM 보고서 |

|---|---|

| 제목 | 비금속광 현대화 채광 연구 [1998] |

| 저자 | 김임호 |

| 언어 | KOR |

| 청구기호 | KR-98-C-12-1998-R |

| 발행사항 | 韓國資源硏究所, 1998 |

| 초록 | An underground mining method was designed for the development of a large Manduck quartzite orebody using softwares such as Datamine, Beap3d of Canmet and a developed code for production cost. Both the evaluation of the stability by a numerical modelling and the analysis of the production cost on the designed method were carried out to obtain the results as follows: 1) Analysis of the geological data and on site investigation over the orebody were carried out in order to evaluate the reserves, composed of 3 high grade veins and 4 medium grade veins, and low grade thin veins of muscovite schist developed between each high and medium grade veins. The reserves was divided into four stopes for the application of the sublevel stoping method. 2) A Sub-level stoping was designed for the development of the reserves. The optimized method can yield as much as 545 tons of ore for every meter of heading. 1.83 meters of tunnel should be driven to produce a thousand tons of ore by taking into consideration the overall length of heading, 9,150 meters. The following table shows the heading length and the development coefficient of each stope. 3)The charging pattern in the first sublevel of a stope was designed with 275.0 grams of explosives composed of 229.1 grams of ANFO and 45.9 grams of Gelatine Dynamite, 296.1 grams of explosives composed of 246.7 grams of ANFO and 49.5 grams of Gelatine Dynamite in the 2nd Sub-level of each stope. A general charging pattern for every ton of production in each row of blasting was designed with 287.1 grams of explosives composed of 239.2 grams of ANFO and 47.9 grams of Gelatine Dynamite. A ton of production will need 0.12 meter of drilled hole in average. 4) Out of 8,938,803 tons of total reserves, 4,991,769 tons can be produced with an average recovery of 56% and 3,947,043 tons equivalent to 44% of the total reserves has to be left for the safety rib pillars, including 1,189,728 tons of the waste in the 2nd stope. 5) The average uniaxial compressive strength and the tensile strength of the three quartzite samples from the Manduck mine lot was 130 MPa and 13.35 MPa respectively. The density was 2,65 g/㎤, the velocity of the P wave 3,255 m/sec and that of the S wave 2,210 m/sec. The quartzite can be ranked as a high to medium strength rock according to the standard classification of the Ministry of Construction and Transportation by taking into consideration the strength of the rock. This quartzite is also ranked as a hard rock after the classification suggested by Deere and Miller according to the uniaxial compressive strength giving a medium elastic modulus ratio. Generally speaking, the quartzite can be ranked a medium to hard rock with a coefficient of brittleness as low as 9.7. 6) The rock around the pillars between the stopes will be mechanically stable during mining and the stability of the stopes can be guaranteed through out the four stopes giving a safety factor above 1.27 in all the pillars by the criterion of Drucker-Prager which was defined with the reevaluated mechanical properties of rock after the rock mass classification.Since mining starts from the bottom 1st Sublevel to the uppermost 2nd Sublevel, the safety of the stopes and the galleries will improve together with the mining process. The rock around the upper most part and the bottom of all the stopes have a very high factor of safety, however a spot reinforcement such as the rock bolting is recommended during the mining operations not only because the intermediate and minor principal stresses are acting in a tensile mode but also because the bedding plane acting as the major principal set of the plane of weakness, which has the same direction of the axis of the stopes. It is imperatively recommended to control the stability of the underground structures throughout the mining from the lower sublevel to the upper sublevel and to evaluate the in situ rock properties and the rock stresses for the future study. In reality, the safety factors in some part of the stope may be worse than the ones calculated in the actual study, because the initial stresses were not measured to carry out the present analysis of stability. 7.The production cost calculated regrading a scale of 200,000 tons was 4,873 won per ton by adding the cost of heading, mining, and hauling, 1,072 won, 1,966 won and 1,835 won respectively to obtain the results as the following table |

| 페이지 | xi, 142 p. |

| 키워드 | 비금속광, 채광, 현대화, 규석광산, 규석 |

| 원문 |

댓글